Understanding Advanced Oil Mist Collection and Air Filtration #

Oil mist collection and filtration systems are essential for maintaining clean air in metalworking environments. These systems are specifically engineered to remove oil mist and smoke generated during machining processes, where metalworking fluids are used for cooling or lubrication. By capturing and filtering airborne contaminants, these systems not only improve air quality but also enable the recovery and reuse of valuable oil.

What Is an Oil Mist Collection System? #

An oil mist collection system, also known as an oil mist air cleaner, is a specialized air filtration solution designed to remove oil mist and smoke from the air. These contaminants are typically produced when metalworking fluids are used during machining. The system not only filters the air but also collects the recovered oil for potential reuse, contributing to both environmental sustainability and cost savings.

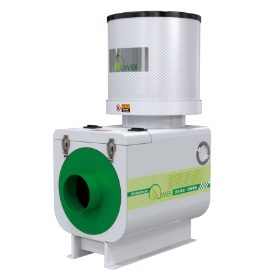

Juwei, a manufacturer based in Taiwan, offers mist collectors and filtration systems that utilize a 3D impact process. This process captures up to 70% of oil mist molecules from incoming air, allowing for their reuse. Subsequent filtration stages ensure that purified air is returned to the workspace. The units are designed for easy integration with existing machinery, minimizing installation costs and maintaining stable operation with low vibration and noise.

The advanced air purification technology employed by Juwei’s oil mist collectors achieves filtration efficiencies as high as 99.95% to 99.995%.

How Does an Oil Mist Air Cleaner Work? #

The oil mist collection process involves several key filtration stages:

-

Initial Filtration – Iron Chip and Particle Screening

The first stage uses a stainless-steel woven mesh at the interface between the machine and the collection system. This mesh acts as a barrier, preventing iron chips and other impurities from entering the air purification system. It is easily removable for cleaning and reuse, reducing maintenance costs. -

Cyclone Filtration

Air is drawn in by a centrifugal fan impeller, creating a cyclone effect that enhances oil collection. The cyclonic action also generates static electricity, which helps oil mist adhere to the stainless-steel mesh. -

Efficient Oil Separation and Collection

A large filter screen with an expanded surface area further optimizes oil recovery. The cyclone flow pattern ensures high filtering performance. -

Centrifugal Filtration

A high-speed centrifugal impeller creates a powerful suction cyclone, forcing oil mist to adhere to the filter’s inner wall. Internal oil baffles efficiently collect the intercepted oil mist. -

HEPA Filtration

The final stage uses a barrel-type HEPA filter to capture any remaining sub-micron mist and smoke particles, ensuring that only highly purified air is released back into the environment. -

Cartridge Filter Options

Juwei offers HEPA cartridge filters in two sizes: 300mm and 600mm. The 300mm filter is suitable for light machining processes, while the 600mm filter is recommended for heavy-duty cutting or applications with significant oil smoke. The larger filter also allows for longer intervals between replacements. For guidance on selecting the appropriate filter, contact Juwei.

For further reading, see the related article: Oil Mist Collectors: A Sustainable Solution for Cleaner Air in Manufacturing.

Key Features of Juwei Oil Mist Collection Systems #

-

3D Impact Principle

Juwei’s unique 3D impact design uses thick, multi-grade woven stainless-steel fibers. These fibers create irregular collisions, encouraging oil mist to adhere to the filter. Accumulated oil droplets are returned to the machine, and the mesh is easily cleaned for extended service life. -

Pleated Filter Material

Circular pleated filter material increases the filtration area, enhancing overall efficiency. -

HEPA Air Purifying Filter

The final filtration stage uses a barrel-type HEPA filter that meets the European H13 standard, with an efficiency rating of 99.97% for 0.3 μm particles. The filter material conforms to EN1882 specifications, achieving 99.95% to 99.9995% efficiency for the most penetrating particle size (MPPS). An optional activated carbon filter is available for odor absorption and further air purification.

Filtration and Recovery Efficiency #

-

Oil Mist Recovery

The initial stainless-steel mesh stage recovers up to 70% of oil mist and processing fluid, with up to 95% of this recovered oil being reusable in machining processes. On-site testing has demonstrated filtration of more than 99.5% of oil mist. -

Continuous Air Quality Improvement

Even when machine tools are idle, running the oil mist recovery air purifier improves ambient air quality in the factory.

Product Series #

For more information about oil mist collectors, accessories, and application guidance, visit the Juwei website.

Oil Mist Collector - R Series

Oil Mist Collector - R Series-V1_9149930570045157646.jpg) Oil Mist Collector-H Series

Oil Mist Collector-H Series